Jade-Pack.

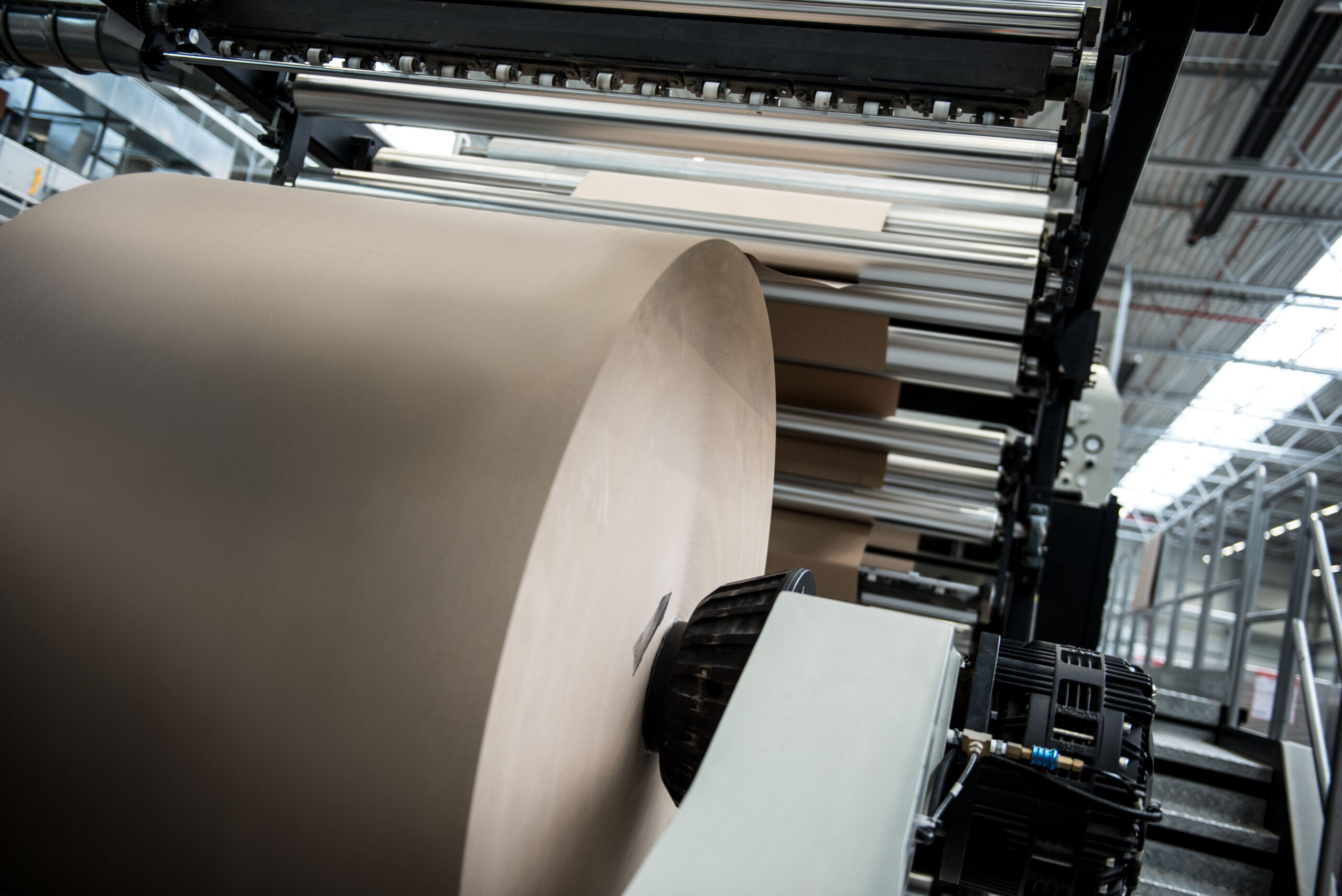

WE DEVELOP AND PRODUCE RAW MATERIALS FOR SUSTAINABLE PACKAGING.

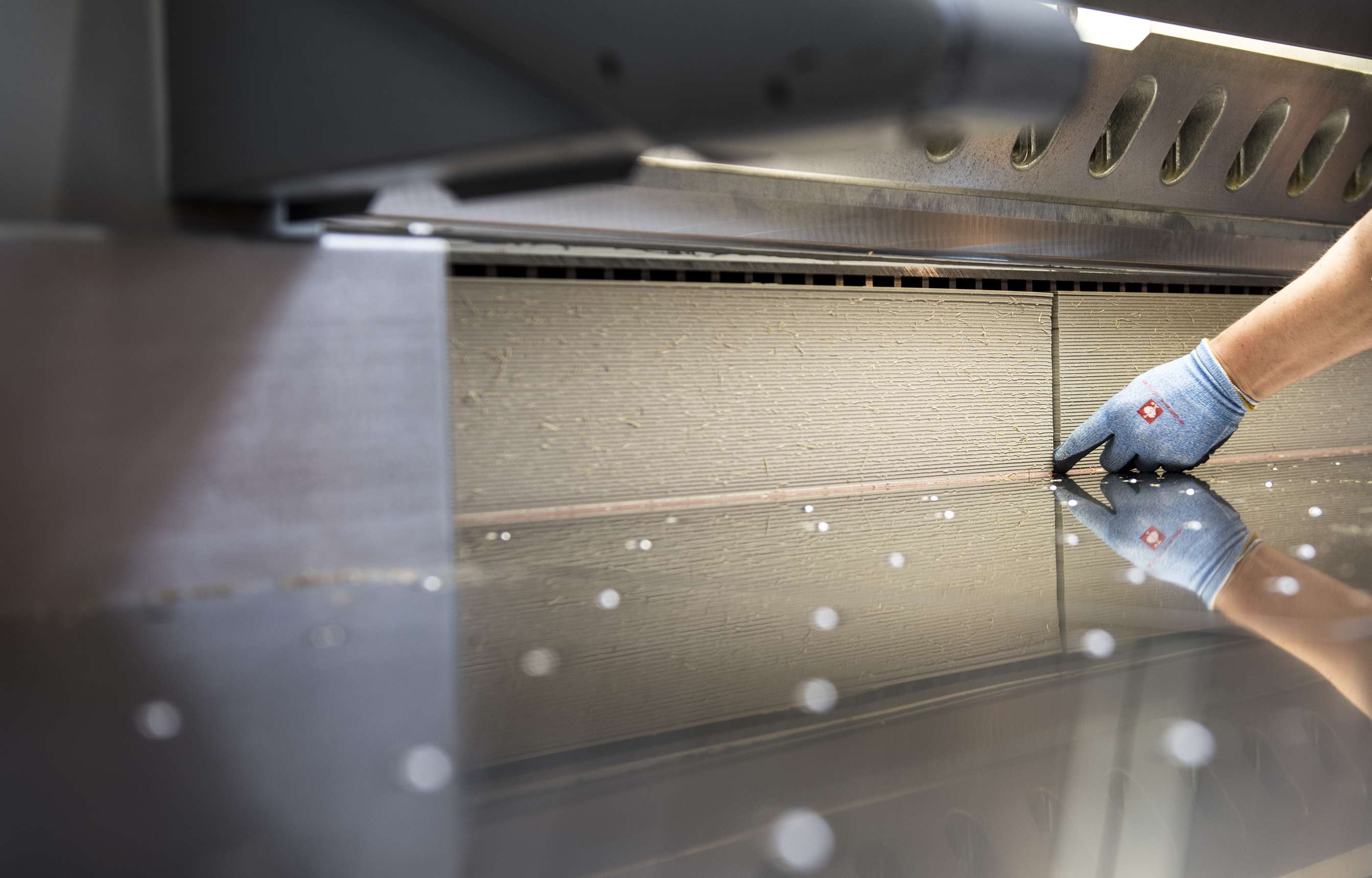

Our products are used by many international food and consumer goods manufacturers. Together with our customers in various industrial sectors, we develop innovative, economically viable and always recyclable product solutions. We ensure a constantly high product quality through a qualified team, a technological lead in production as well as quality assurance in accordance with international food hygiene and quality standards.

- Our customer base is international: cardboard converters · food manufacturers · the automotive supplier industry

- In product development, we work together with our customers from various industrial sectors on a project-oriented basis and in a spirit of mutual trust

- We are part of a highly innovative group of companies with a high level of supply reliability

Our fibre-based laminates for food packaging and industrial applications have a high recycling content and achieve the required technical function without or, if technically required, extremely low percentage of polymers:

- Circular economy: In general, recyclability is a precondition for the development of our products

- Extensive replacement of PE and PET by fibre-based laminates

- Minimising the use of plastics to ensure necessary technical functions, use of ultra-thin mono films in combination with water-based dispersions

- Consistent use of recycled paper and cardboard in the core of the products or on the non-food side

Employees

Production area in m²

Storage area in m²

Grammage in g/m²

Processing capacity in t